Asbestos Awareness is a phrase we have all heard, but do we really know what it is?

Asbestos is a naturally occurring mineral which has been used as a construction material for thousands of years. However, it was the Industrial Revolution that introduced asbestos into  commercial use, specifically due to its wide range of properties.

commercial use, specifically due to its wide range of properties.

The fire-resistant, flexible, and relatively durable mineral was used as an additive that was commonly processed into mechanical equipment and building materials of the 1900s. Such commercial machines and equipment includes gaskets, electrical insulators, and temperature sensitive devices like boilers or generators. The construction industry utilized asbestos in common building materials such as concrete, insulation, roofing products, floor and ceiling tiles, paints and adhesives, to name a few.

Reaching peak consumption by the 1970’s, asbestos was praised as the miracle mineral used across dozens of industries. However, as medical studies of the era started to focus on the long-term health effects of asbestos, it became clear the beloved additive could be contributing to some extremely deadly and rare lung diseases.

________________________________________________________________________________________________________

So why is Asbestos so dangerous?

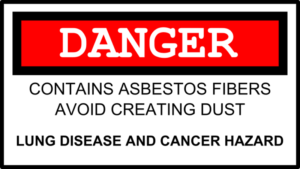

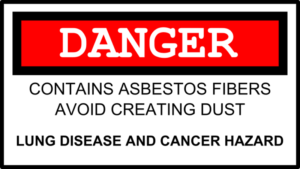

In the last forty years or so, asbestos has been globally acknowledged as a carcinogenic material that causes particular harm to unprotected individuals that accidentally inhale or ingest its fibres. Additionally, these microscopic particles can be carried by the wind, stick to fabrics, or contaminate open water sources resulting in secondhand exposure. After entering the body, the carcinogenic fibrils can attach to the lungs, causing damaging inflammation, scar tissue generation, and eventually mesothelioma cancer. Although it’s been known for quite some time that asbestos exposure is directly tied to mesothelioma and other asbestos-related lung diseases such as asbestosis, only 60 countries (including the EU) have entirely banned it. Therefore, EU safety standards, compliance policies, and health statistics vary greatly from those of the U.S.

Asbestos in the EU

- In 2005, 53 countries in the EU banned asbestos. Prohibiting mining, importation, and use.

- In 2015, HSE reported approximately 2,536 mesothelioma related deaths in Great Britain alone

- Mesothelioma related deaths are projected to decline by the early 2020s

Asbestos in the U.S.

- Asbestos has not been banned in the United States. However, the EPA attempted to ban it in the early 1980s. The ruling was quickly overturned

- Some products made in the U.S. are grandfathered to contain up to 1% asbestos

- In 2015, OSHA reported approximately 2,597 mesothelioma related deaths

- Mesothelioma related deaths are predicted to decline by the late 2020s

Due to decades of continuous use and inconsistent global policies, asbestos remains a prevalent threat and the related diseases associated with asbestos, are rarely detected early-on. Mesothelioma, in particular, develops symptoms slowly, sometimes decades after initial exposure, and commonly mimics other illnesses like pneumonia. Unfortunately, delayed treatment due to misdiagnosis, often contributes to the less than ideal mesothelioma survival rate.

________________________________________________________________________________________________________

Who should take an Asbestos Awareness Course?

According to current regulations (The Control of Asbestos Regulations 2012), all employers have a legal duty to provide information, instruction and training to any employees who are likely to be exposed to Asbestos Containing Material (ACMs) as part of their work.

Taking these precautions could avoid lengthy, expensive legal compensation and save lives!

Tradespersons

According to the Health and Safety Executive (HSE), asbestos kills 20 tradesmen every week. It is, therefore, important that self-employed individuals, contractors and workers are appropriately trained, can protect themselves, and avoid putting others at risk of exposure. These include, demolition and construction workers, general maintenance staff, electricians, plumbers, gas fitters, roofers and plasterers.

Licensed Contractors

Where employees are undertaking higher risk work with asbestos, employers must hold a licence granted by the HSE before commencing any work with asbestos material. Licensed Contractors should have an in-depth understanding of asbestos and its dangers and know how to safely remove and dispose of asbestos material.

Building Owners

If you are a building owner, and/or are responsible for the maintenance or repair of non-domestic premises, you have a duty of care to manage any asbestos in that building.

This duty covers all non-domestic premises including industrial and commercial buildings such as factories, warehouses, offices and shops. Public buildings such as hospitals, schools and leisure centres are also included in this duty.

Although the duty to manage asbestos does not extend to private domestic buildings, it is relevant to communal areas of multi-occupancy premises such as flats.

As a duty holder, what do you need to know?

It is your responsibility to find out if asbestos is present in your building. Once this has been established, the location, condition and type of asbestos must be recorded and risk assessed. Any identified risks should be managed and monitored by way of an action plan. These plans should be made available to any tradesperson working at your premises.

Members of the public.

If undisturbed and in good condition, asbestos is unlikely to cause harm. However, it would be wise that homeowners and tenants are aware of asbestos and where to go for advice if needed. Further information and guidance can be found at http://www.hse.gov.uk/

_________________________________________________________________________________

What training do you need and where to find it?

The type of training you require will ultimately depend on your level of involvement with and potential exposure to Asbestos material.

VinciWorks offers a UKATA (Category A) Asbestos Awareness Certified eLearning Course.

This two-hour course is an essential prerequisite for any Tradesperson who is likely to come into contact with ACMs and has been certified by the United Kingdom Asbestos Training Association (UKATA). This modular course provides an in-depth range of key topics including all relevant requirements: The Control of Asbestos Regulations 2012, Regulation 10, and the Approved Code of Practice L143 second edition, Managing and Working with Materials Containing Asbestos.

prerequisite for any Tradesperson who is likely to come into contact with ACMs and has been certified by the United Kingdom Asbestos Training Association (UKATA). This modular course provides an in-depth range of key topics including all relevant requirements: The Control of Asbestos Regulations 2012, Regulation 10, and the Approved Code of Practice L143 second edition, Managing and Working with Materials Containing Asbestos.

Successful completion of the UKATA Category A Certified Online Asbestos Awareness Course, will provide users with the knowledge needed to identify the presence of asbestos, the different types of asbestos, the health risks associated with exposure to asbestos material and highlight the importance of safe working practices.

________________________________________________________________________________________________________

What are the benefits of being Asbestos Aware?

Ensuring your employees have taken a course with verified content and UKATA certification will provide obvious health and safety benefits. Furthermore, it will improve your staff’s knowledge and skill set and reinforce your organisation’s reputation, credibility and business success within your industry.

From this list of pros and cons we can see that provided you have a great teacher and that students start with a similar level of knowledge and ability, classroom teaching is a good way of making sure that people understand the theory and “buy-in” to the principles presented. However, since online learning courses don’t depend on everyone having the same ability they can be really useful in bringing people up to the same level, for example before a classroom course. Online courses are also useful for refresher training, as they are easy to schedule and access. Knowledge can be tested effectively by both classroom and online courses, but that knowledge needs to be reinforced in the workplace and provided it can be done safely and recorded, checking competence is best done on-the-job. Online learning is automatically recorded by the learning management system, so where the same online learning management system can also be used to schedule, test and record classroom attendance and on-the-job training, the administration will be a lot easier.

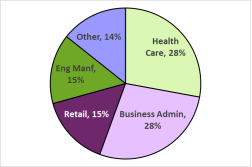

From this list of pros and cons we can see that provided you have a great teacher and that students start with a similar level of knowledge and ability, classroom teaching is a good way of making sure that people understand the theory and “buy-in” to the principles presented. However, since online learning courses don’t depend on everyone having the same ability they can be really useful in bringing people up to the same level, for example before a classroom course. Online courses are also useful for refresher training, as they are easy to schedule and access. Knowledge can be tested effectively by both classroom and online courses, but that knowledge needs to be reinforced in the workplace and provided it can be done safely and recorded, checking competence is best done on-the-job. Online learning is automatically recorded by the learning management system, so where the same online learning management system can also be used to schedule, test and record classroom attendance and on-the-job training, the administration will be a lot easier. As shown in the pie chart, three service sectors together represent 7 out of every 10 apprenticeships, with engineering and manufacturing coming a close fourth. Of these, health and social care is the biggest growth area, with apprenticeships starts bucking the overall trend by increasing during the year.

As shown in the pie chart, three service sectors together represent 7 out of every 10 apprenticeships, with engineering and manufacturing coming a close fourth. Of these, health and social care is the biggest growth area, with apprenticeships starts bucking the overall trend by increasing during the year. The stereotypes of baby boomers (born between 1946 and 1964), generation X (1965 to 1979), millennials or Gen Y (1980 to 1995) and post-millennials or gen Z (those born since 1996) should be treated with caution since any generation has more differences than similarities. However, considering the experience of each is useful when deciding how to provide training. Baby boomers and generation X will remember blackboards at school, and at the younger end, whiteboards using odorous pens. Post-millennials joining the workplace now might never have seen a blackboard, and their whiteboards were connected to the Internet and touch sensitive.

The stereotypes of baby boomers (born between 1946 and 1964), generation X (1965 to 1979), millennials or Gen Y (1980 to 1995) and post-millennials or gen Z (those born since 1996) should be treated with caution since any generation has more differences than similarities. However, considering the experience of each is useful when deciding how to provide training. Baby boomers and generation X will remember blackboards at school, and at the younger end, whiteboards using odorous pens. Post-millennials joining the workplace now might never have seen a blackboard, and their whiteboards were connected to the Internet and touch sensitive. people like doing – using computers! One such approach is the

people like doing – using computers! One such approach is the  has increased steadily since 2011/12. Some of these young people lack confidence. Making e-learning accessible to them – on computers at work, but also allowing them access on their own mobile devices, out of work time if they choose – means that they can repeat a lesson as often as they want until they feel confident. If attention deficit is a problem, an e-learning solution that allows students to break their learning into chunks of time that suits them has additional value. Ten minutes while they wait for the bus; five minutes when they get into work in the morning. It all adds up and will help everyone (not just those with specific learning needs) to take information in.

has increased steadily since 2011/12. Some of these young people lack confidence. Making e-learning accessible to them – on computers at work, but also allowing them access on their own mobile devices, out of work time if they choose – means that they can repeat a lesson as often as they want until they feel confident. If attention deficit is a problem, an e-learning solution that allows students to break their learning into chunks of time that suits them has additional value. Ten minutes while they wait for the bus; five minutes when they get into work in the morning. It all adds up and will help everyone (not just those with specific learning needs) to take information in.

e wrong time and then a further session through illness or work commitments and suddenly that person may go 6-months or more without the necessary training.

e wrong time and then a further session through illness or work commitments and suddenly that person may go 6-months or more without the necessary training. commercial use, specifically due to its wide range of properties.

commercial use, specifically due to its wide range of properties.

prerequisite for any Tradesperson who is likely to come into contact with ACMs and has been certified by the United Kingdom Asbestos Training Association (UKATA). This modular course provides an in-depth range of key topics including all relevant requirements: The Control of Asbestos Regulations 2012, Regulation 10, and the Approved Code of Practice L143 second edition, Managing and Working with Materials Containing Asbestos.

prerequisite for any Tradesperson who is likely to come into contact with ACMs and has been certified by the United Kingdom Asbestos Training Association (UKATA). This modular course provides an in-depth range of key topics including all relevant requirements: The Control of Asbestos Regulations 2012, Regulation 10, and the Approved Code of Practice L143 second edition, Managing and Working with Materials Containing Asbestos.